De hoogste kwaliteit in combinatie met uitstekende prestaties heeft een naam: MOTOMAN

Socket welding for high-tech gas cylinders - Handling and welding robots work “arm in arm”

Valve sockets are a key element of gas cylinders: they enable secure and gas-tight connection of regulators and fittings to the cylinder. At ALUGAS, around 1,000 sockets are welded every day – and as of recently the work is now fully automated. For this purpose, system builder Roland Ruegenberg based in Bad Sobernheim designed a system centred around two MOTOMAN industrial robots by Yaskawa. These literally work “arm in arm”, taking care of both the entire parts handling and the welding process.

- Industrieën

- Metaalbewerking

- Toepassingen

- Booglassen

- Handling

- Klant

- Roland Ruegenberg GmbH

- Producten

- AR900 - AR serie

- GP12 - GP-serie

ALUGAS wants nothing less than to “make life easier” for its customers. And they mean it quite literally, too: campers and barbecue chefs swear by the company’s pressurised containers for liquefied gases such as propane and butane (LPG), as do forklift drivers and tradespeople. This is because the high-tech gas cylinders from Bad Sobernheim are up to 50 per cent lighter than conventional steel cylinders, making them ideal for mobile use – whether at work or in the sports and leisure sector.

A welding cell for the supreme discipline

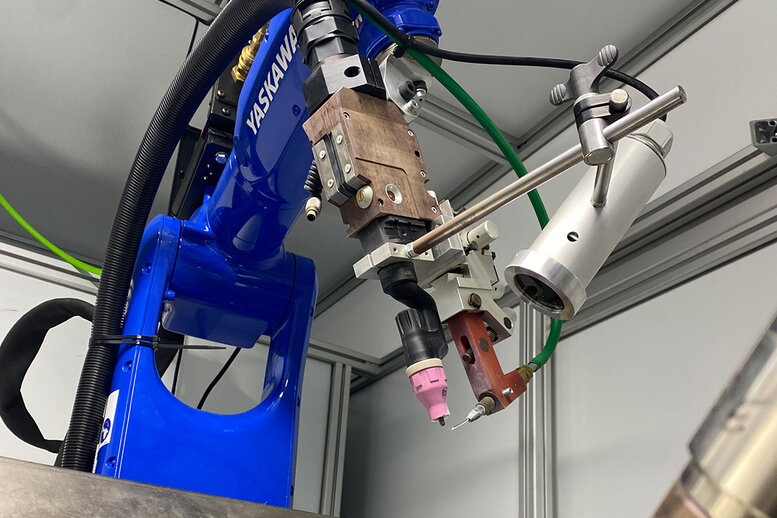

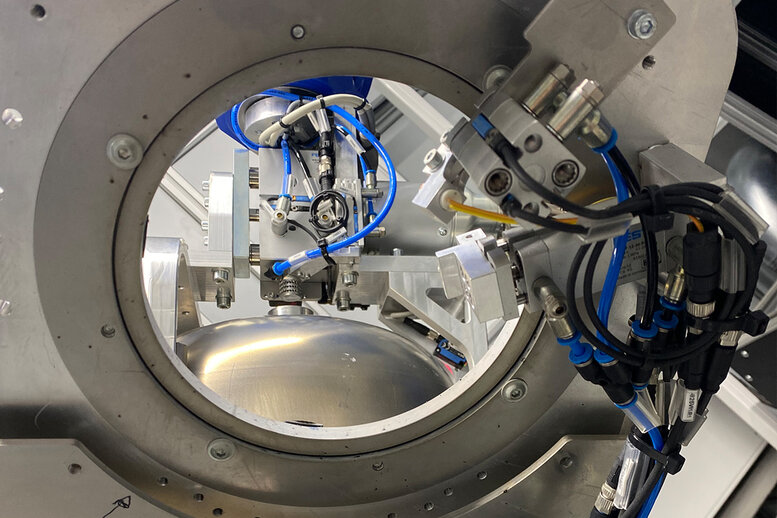

Valve sockets are a key element of gas cylinders since they perform key functions relating to safety and connectivity. ALUGAS currently combines four socket models with three different sized half-shells, enabling it to offer a wide range of cylinders for all applications. Previously the sockets were welded onto the half-shells by means of a semi-automatic system. However, this became outdated and no longer met the more rigorous, state-of-the-art requirements. A new welding solution was therefore required – and not an “off-the-shelf” option. After all, aluminium exhibits distinctive properties and behaviour, including a very high level of thermal conductivity. This requires more specialised processing than other metals such as steel. Cold wire TIG welding (tungsten inert gas) is ideally suited to welding aluminium: it allows very precise control over the heat input and is ideal for applications where high precision and clean weld seams are important.

However: “Cold wire TIG welding is the supreme discipline in aluminium welding and requires precise temperature control of the workpieces,” explains Dominik Sperling, project engineer with system builder Roland Ruegenberg GmbH. This was the company ALUGAS turned to in its search for a partner to revise and build its customised welding cell.

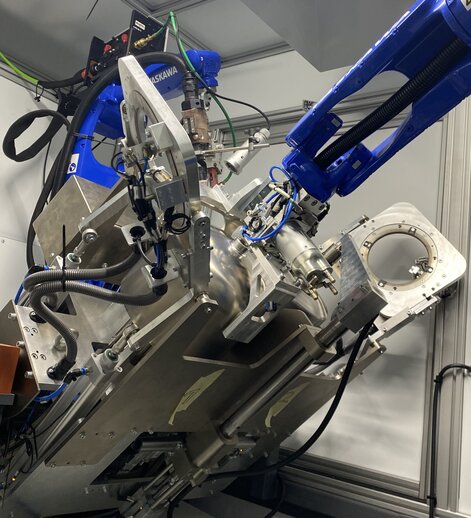

Customer requirement: a compact system suitable for sea containers

In addition to its various half-shell/socket combinations, ALUGAS also had other requirements: they needed the option to expand their portfolio, and in order to be able to maintain existing production processes, an autonomy time of 30 minutes had to be adhered to. Yet another key requirement: the system had to be suitable for sea containers. “There were two reasons for this. Firstly, ALUGAS was planning a new site overseas which was to have the same system as the main plant, and secondly, it had to be possible to move the system at the German site without a great deal of effort; we had to take into account the fact that some passageways are very narrow,” says Dominik Sperling. Ruegenberg specialises in precisely this type of challenge in the development of fully automated production systems: “We find solutions to seemingly impossible tasks” – such is the company’s ambitious claim. Ruegenberg developed an astonishingly compact system. It not only contains two welding fixtures with a preheating function: the preliminary process of laser marking of the sockets and the downstream inspection are integrated, too. Yet the whole thing is still designed so that the individual modules can easily be separated and reassembled – so they fit easily into a sea container. The fact that all processes are carried out on a surface area of just 3 x 5 metres is down to two Yaskawa MOTOMAN industrial robots. These take care of the entire component handling and welding process: “All relevant handling processes are taken care of parallel to the individual welding processes, so capacity utilisation is optimum,” explains Sperling.

The system is fed manually – the-half shells weighing around 2 kg via roller conveyors and the sockets via a feed conveyor with buffer. They are automatically separated, then the sockets are labelled with a DMC code by means of an integrated laser and heated to the required preheating temperature on a temperature-controlled accumulation section. A Yaskawa AR900 welding robot takes care of burner control during the fully automatic welding process. Now fitted with a socket, the half-shell is transferred to a geometry inspection station by a MOTOMAN GP12 handling robot. Here, the weld root and top layer are checked, with AI-supported pore detection. Finally, the welded and tested half-shells are discharged via roller conveyors.

Two MOTOMAN robots deployed

For the designers at Ruegenberg, the MOTOMAN GP12 was the optimum solution for the new system: thanks to its slim arm design, it can also be used in very confined spaces, and its short acceleration and braking times make it the world’s fastest industrial robot for payloads of up to 12 kg. Its fast and highly dynamic servomotors from Yaskawa’s own Sigma 7 series are particularly powerful, enabling high-precision work at very high cycle rates. “For us, robotics is an indispensable tool in automation,” says Sperling. But Ruegenberg had previously only used the robots for handling processes. With the ALUGAS system, the company was moving into new territory: for the first time, Ruegenberg installed a MOTOMAN AR900 – a compact 6-axis welding robot. The models in the AR series were specially developed to meet the rigorous requirements of arc welding. They guarantee particularly short process times, which means a high level of efficiency and energy savings – while still ensuring outstanding path accuracy and stability. The AR900 is able to make full use of its flexibility in the ALUGAS system: with its six axes, it can weld the sockets fully onto the half-shells without a break. “The MOTOMAN AR900 has an integrated interface to the welding source of EWM welding machines. This allows us to control the parameters and programmes according to requirements and adapt the welding position individually to each welding process. By creating individual programmes for the respective welding application, we can reduce set-up times enormously,” says Dominik Sperling enthusiastically. It was not only the AR900 itself that Sperling was impressed by, but also the co-operation with Yaskawa: “In the search for robotics manufacturers who were able to put our ideas into practice, Yaskawa proved to be a reliable and customer-oriented partner who is on hand with help and advice, too.”

Output significantly increased The new system and the two Yaskawa robots have impressed ALUGAS’s clients, too, enabling the company to modernise and improve one of its core processes in the production of aluminium gas cylinders. The entire marking, welding and testing process is now taken care of by a modular and compact system. The fully automated welding process with constant and regulated parameters guarantees consistent quality and capacity utilisation, with an autonomy time of 30 minutes. What is more, employees no longer need to intervene, which means that worker retention is reduced and highly qualified specialist staff can be deployed elsewhere in the company.

Author and contact for readers’ enquiries:

Björn Matern

Sales Area Manager

Yaskawa Europe GmbH, Robotics Division, Allershausen

Phone: +49-8166-90-0

robotics@yaskawa.eu

www.yaskawa.de